Mission Statement

“To deliver integrated design, processes, engineering and solutions, through construction, project management and infrastructure to the highest standards of quality, safety and customer satisfaction benefiting the company, all stakeholders, communities and the environment."

Featured Projects

-

Sydney Desalination Plant

VIEW PROJECT

Sydney Desalination Plant

VIEW PROJECT

-

The Canberra Light Rail Project

VIEW PROJECT

The Canberra Light Rail Project

VIEW PROJECT

-

Cronulla WWTP – SCADA & Electrical Upgrade

VIEW PROJECT

Cronulla WWTP – SCADA & Electrical Upgrade

VIEW PROJECT

-

West Camden WRP – New Digesters & Upgrade

VIEW PROJECT

West Camden WRP – New Digesters & Upgrade

VIEW PROJECT

-

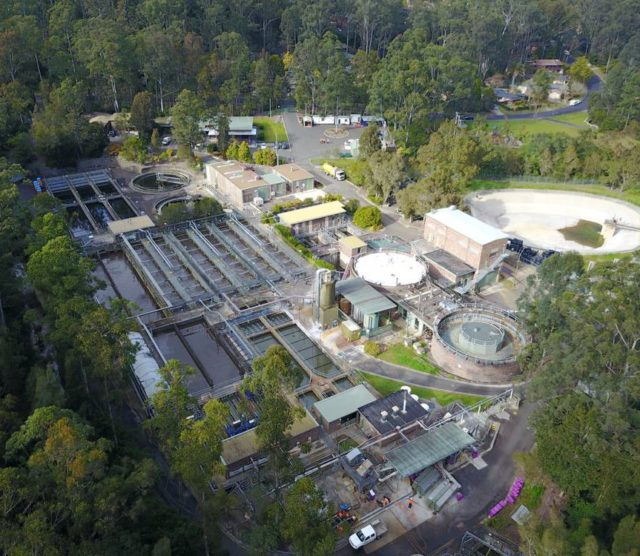

West Hornsby WWTP – SCADA & Electrical Upgrade

VIEW PROJECT

West Hornsby WWTP – SCADA & Electrical Upgrade

VIEW PROJECT

-

Warriewood WWTP – Amplification & Upgrade

VIEW PROJECT

Warriewood WWTP – Amplification & Upgrade

VIEW PROJECT

-

Warragamba WRP – SCADA, Electrical, & Accommodation Upgrade

VIEW PROJECT

Warragamba WRP – SCADA, Electrical, & Accommodation Upgrade

VIEW PROJECT

-

St Mary’s WRP – SCADA & Electrical Upgrade

VIEW PROJECT

St Mary’s WRP – SCADA & Electrical Upgrade

VIEW PROJECT

-

Bombo WRP – SCADA & Electrical Upgrade

Design

VIEW PROJECT

Bombo WRP – SCADA & Electrical Upgrade

Design

VIEW PROJECT

-

Bondi WWTP – SCADA & Electrical Upgrade

Design

VIEW PROJECT

Bondi WWTP – SCADA & Electrical Upgrade

Design

VIEW PROJECT

Get in touch with us

Call us at +61 (0)2 9854 6100 or use the form below to learn how we can help you.